Checkweighers for live poultry

Checkweighers for live poultry

Innovation, which is Vendée Concept’s priority, is at the heart of our constant improvement process.

In this article, discover the new inventions developed by our teams in the field of live poultry.

Checkweigher CALIBRA T QUARTZ

Checkweigher CALIBRA T QUARTZ

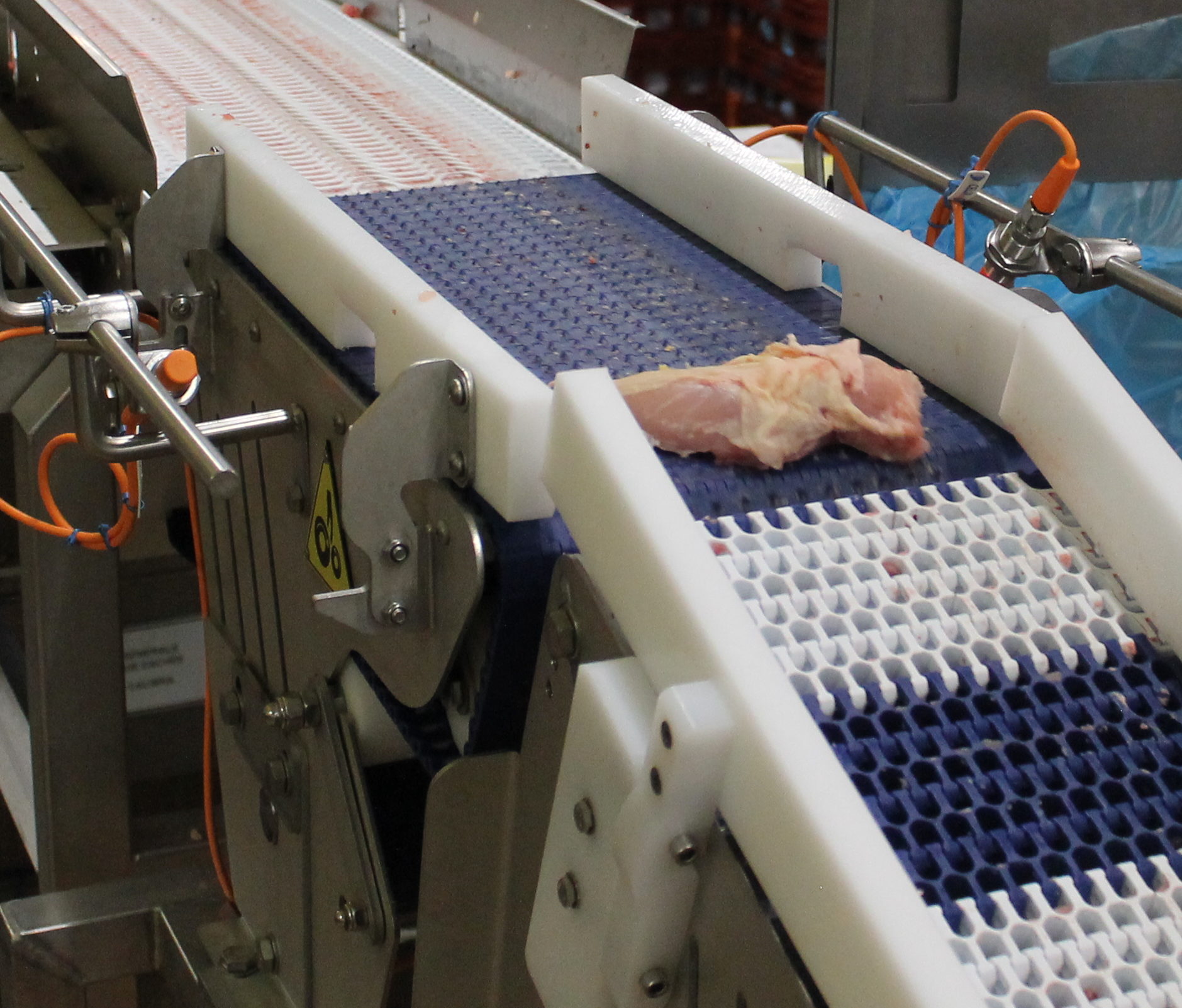

Dynamic, fast and accurate weighing. Robust and patented modular belt. Discover the certified checkweigher CALIBRA T QUARTZ. Made in France.

The checkweigher CALIBRA T QUARTZ is composed of a weighing platform allowing to calibrate in movement all types of products, bare or packed. The 8” touch screen allows the programming of the different calibres. The management software offers you a panel of possible programming.

Inteligent conveyor CALIBRA OVA-B

Inteligent conveyor CALIBRA OVA-B

The inteligent conveyor CALIBRA OVA-B allows an increase of your productivity !

First of all he improves the instant rate up to 20% extra.

Then he adjust the supply of products in real time upstream of a Vendée Concept weighing conveyor CALIBRA CD for a better optimisation of the weighing of the products

Compact video oyster grader CALIBRA CCV

Compact video oyster grader CALIBRA CCV

The compact video oyster grader has been specially conceived to serve the needs of space optimization in oyster-farming’s production areas.

The CALIBRA CCV sort products by size (length, width) thanks to a video system embedded on the brought up conveyor. The oysters are then led towards a smart motorized deflector. The oysters are deviated delicatly towards reception channels composed of automatic trapdoors.

Robot integration

Robot integration

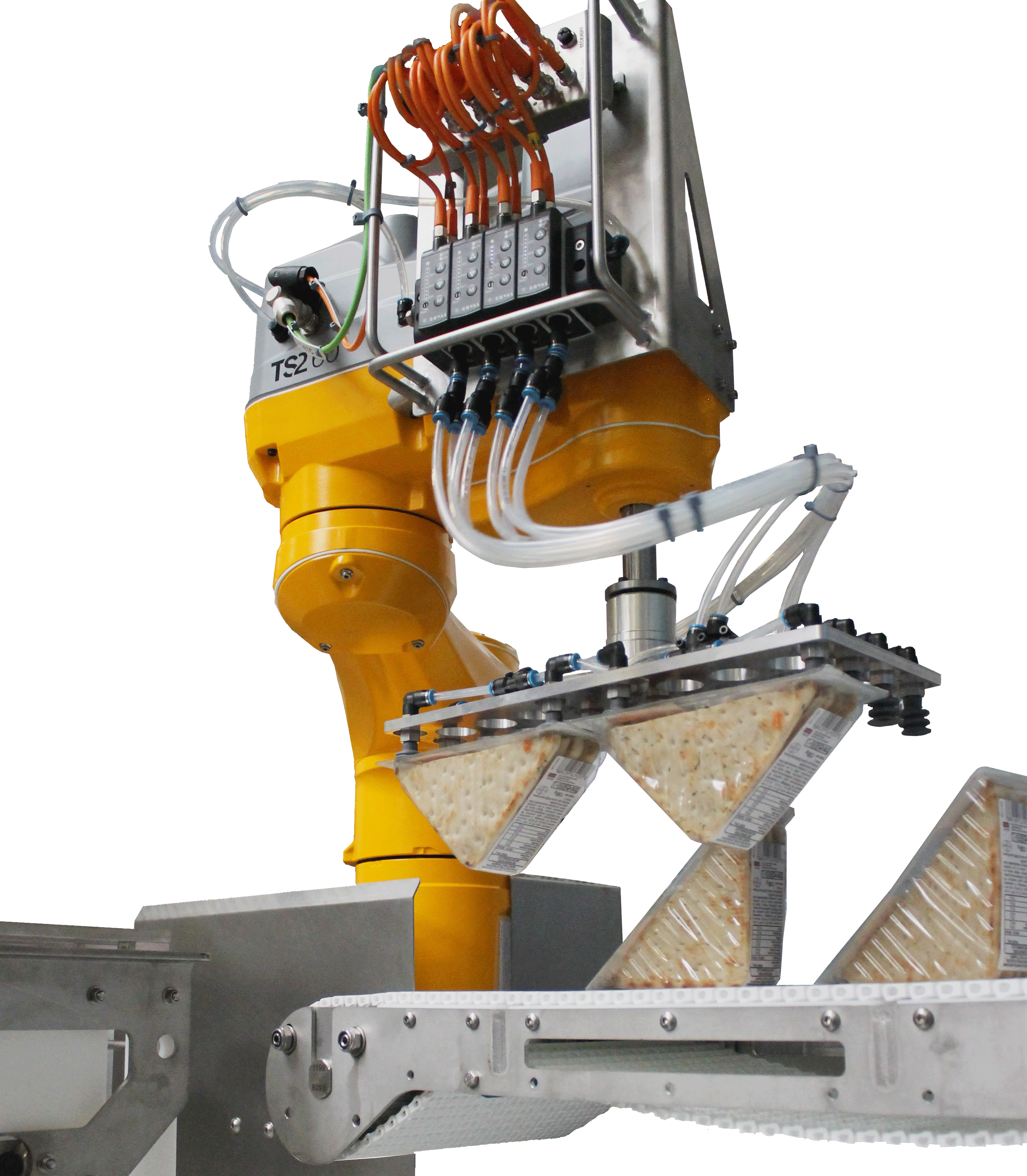

The robot integration in the food industry is proposed from now on by Vendée Concept. Available for several applications in the poultry, seafood, meat or elaborated products sectors.

Also, the robot is equipped with and adaptable gripper and customised to the diffrent food industry applications, fully created by Vendée Concept, the integration of robots to production lines that already exists is now possible thanks to a partnership with Stäubli.

Moreover a fixed weight association is possible with a weighing bridge CALIBRA CD and a checkweigher CALIBRA T Vendée Concept.

Compact oyster grader

Compact oyster grader

The new compact oyster grader Vendée Concept has been specially conceived to serve the needs of space optimization in oyster-farming’s production areas.

First of all, this oyster grader is ultra compact but also very precise. She can achieve up to 10 000 oysters/hour !

Thanks to its new deflector system, the oyster grader Vendée Concept brings more robustness and a significant decrease of maintenance costs to grade your oysters.

The new oyster grading process combine a timer conveyor with cleats in modular belt, a weighing bridge Vendée Concept and an innovative ejection system by motorized deflectors.

Following the calibre, the oysters are led thanks to stainless steel elbows towards reception channels composed of manual or automatic trapdoors.

To conclude the power supply of the oyster grader is 100% electric (220 Volt outlet),

Associative weigher CALIBRA OPEZ-B

Associative weigher CALIBRA OPEZ-B

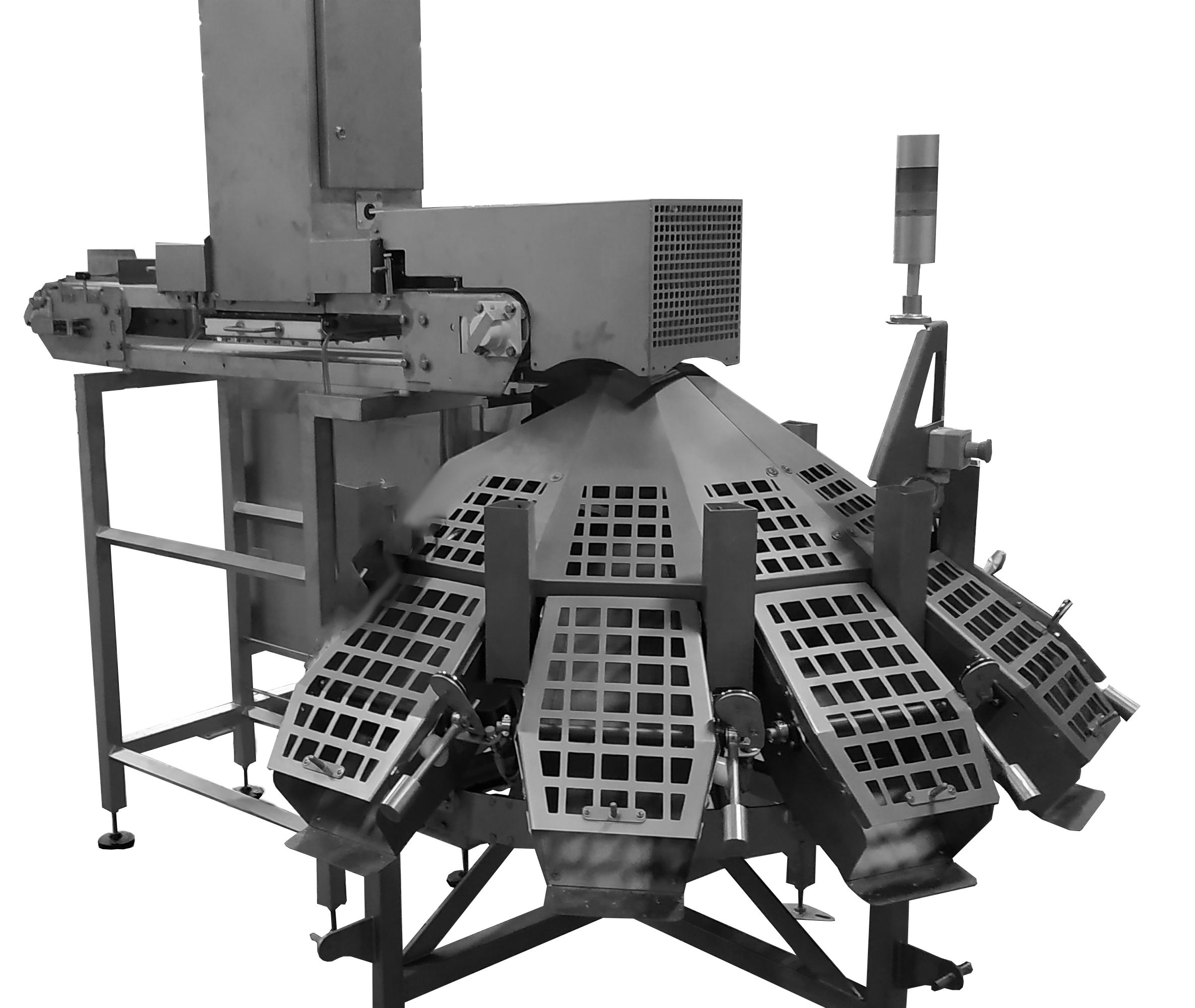

The CALIBRA OPEZ-B works in two stages. The upper part is used to place products. There are seven weighing buckets that discharge in 14 buffer hatches with angular opening (two for each bucket). Each product have to be placed individually in one of the 7 buckets. When a product has been weighed, the bucket swivels by 90° and places it on the buffer hatch. At that moment, the program calculates the better combination in order to match the targeted weigh.

Individualized deboning and cutting line, Station line

Individualized deboning and cutting line, Station line

Calibra SL Station Line is a smart slaughter line. Which allows the realization of de-boning/trimming operations per work station. The objective is to handle products supplying for each operator work space directly from a computer. This process is the best way to minimize issues related to products coming to fast or too slow and creating some delay in treatment. It also enhances implementation of the working space and limit the handling of products by operators.

Overhead grader Calibra LA trays

Overhead grader Calibra LA trays

The overhead grader ergonomics has been studied to preserve your employees’ health. In response to the sick leave and musculoskeletal diseases problematic, Vendée Concept has developed the tray overhead grader, a practical and ergonomic process which reduces the risk of professional diseases.

The poultry parts previously cut on the cone line are placed by operators on the trays passing in front of their workstation. This new working way is ergonomic because the operators stay on a comfortable working area. To place the poultry parts, the movement is not going over the elbow height; it prevents tendinitis and unnecessary movement. The overhead system enhance your working areas.